行业动态

产品

联系嘉瑞杰

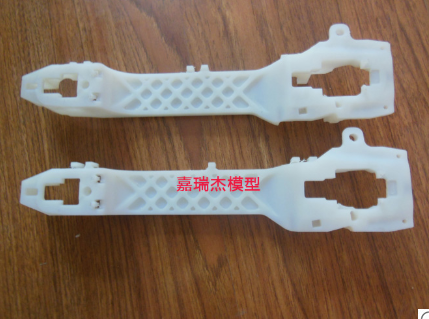

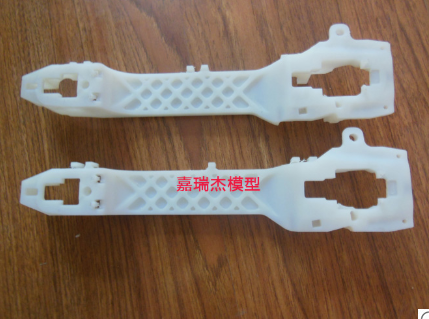

手板制作步骤之手工处理

来源:http://dcjzl.com作者:哈希28单双发布时间:2022-11-22

其实这一步骤在整个流程比重中占有较大的一部分,一个手工师傅的技艺精不精湛也直接影响到济南手板装配,及手板外观问题,包括手板一些小细节的把握!

In fact, this step accounts for a large part of the whole process. The craftsmanship of a craftsman has a direct impact on the assembly and appearance of the Jinan prototype, including the grasp of some small details of the prototype!

1.毛边:CNC加工下来后,手板件周围是有很多毛刺的,这只需要用三角刀按周边轻轻绕一圈就能处理干净了,当然尼龙等坚韧材料毛刺很难处理,非常影响外观,有外观要求手板一般不建议用这种材料。

1. Remove burrs: after CNC processing, there are many burrs around the hand board, which can be cleaned by gently winding around the periphery with a triangular knife. Of course, the burrs of nylon and other tough materials are difficult to handle, which greatly affects the appearance. It is generally not recommended to use this material for hand boards with appearance requirements.

2.核对尺寸:手工是对手板尺寸的初次检查,若有尺寸不合格产品也可直接向CNC反应重做,这样做的好处在于可以迅速反应节省成本不会浪费太多时间,若产品已经做好才发现尺寸问题那不仅增加成本同时也耽误了交期。

2. Size check: Handwork is the initial inspection of the size of the hand board. If there are unqualified products, they can also be directly reported to the CNC for rework. The advantage of this is that it can quickly respond and save costs without wasting too much time. If the product has been well prepared, it will not only increase the cost but also delay the delivery.

3.粘接:有些尺寸过大超出机台加工范围或结构复杂难以加工到位的,手板厂一般选择拆件做,手工这一步需要把这些拆件按图纸粘回原样,要注意的是一定要粘接平整无缝,不然很影响手板尺寸,外观及装配!对于这一点,相信很多手工师傅还是非常有经验的

3. Bonding: For those whose size is too large to be processed on the machine or whose structure is complex and difficult to be processed in place, the prototype factory usually chooses to disassemble them. In the manual step, these disassembled parts need to be glued back to the original shape according to the drawings. Note that the bonding must be smooth and seamless, otherwise the size, appearance and assembly of the prototype will be affected! For this, I believe that many craftsmen are very experienced

4.装配:通常来说装配分为两步,初步为CNC拿过来后的装配叫配白板:手工按照图纸对产品特征及装配位加以精修,使产品组装通顺,更加精致!这一过程也能及时发现设计上的缺陷,并做到随时跟客户沟通!二步为手板喷油完成后手工再装机:其实到这里手工只要对手板各部件进行再组合,一款漂亮的手板模型也基本完成。

4. Assembly: Generally speaking, assembly is divided into two steps. The assembly after CNC is taken is called white board: the product features and assembly positions are refined manually according to the drawings to make the product assembly smooth and more refined! This process can also find design defects in time and communicate with customers at any time! The second step is to manually re install the machine after the completion of hand injection: in fact, a beautiful hand model is basically completed as long as the hand parts are manually re assembled here.

手工其实是后处理工艺的一个步骤,主要包含毛边、核对尺寸、粘接、装配。以上就是讲解的详细内容了,您对此有什么了解可以随时来我们网站http://dcjzl.com进行咨询!

Handwork is actually a step of post-treatment process, mainly including removing burrs, checking dimensions, bonding and assembly. The above is the detailed explanation. You can come to our website at any time if you have any information about it http://dcjzl.com Consult!

下一篇:产品设计中手板制作的原因

相关资讯

手板制作加工时注意事项

2024-04-11手板加工如何服务好客户?

2024-04-09手板加工的过程及方式

2024-04-06快速成型的基本原理构成有哪些?

2024-02-27工业产品设计中常见手板件的制作方式

2024-02-23ABS手板模型的优势有哪些?

2024-02-21铝合金手板模型制作手法与维护

2024-02-10铝合金手板模型的氧化工艺介绍

2024-02-10汽车手板模型制作的低压灌注工艺

2024-02-06手把手教你怎么选机箱机柜定制工厂

2024-01-27